Forged Through Fire, Built for the Future

1939 – 1971

A Humble Beginning

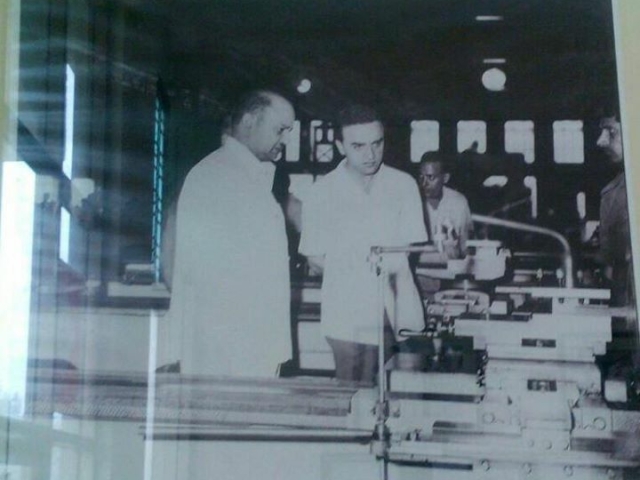

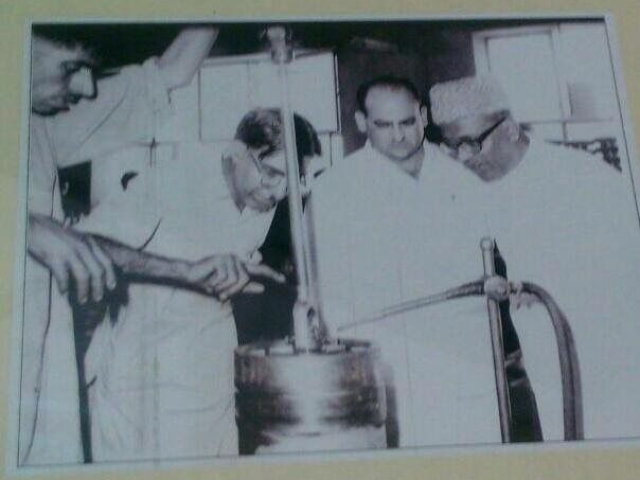

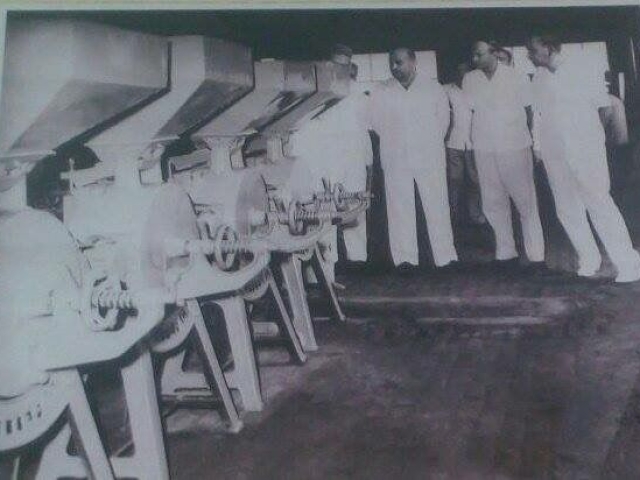

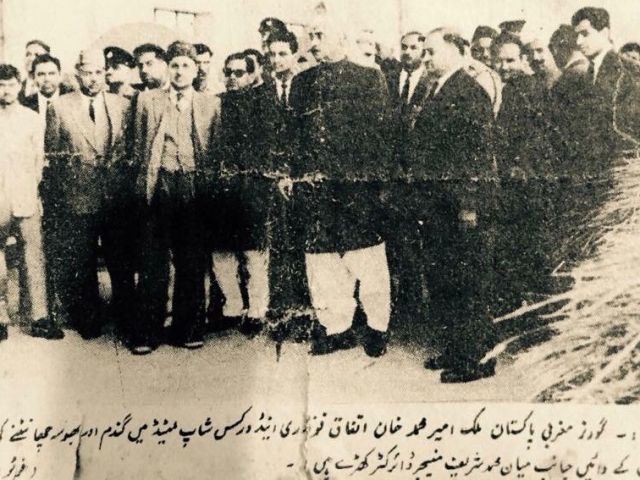

In 1939, in the bustling city of Lahore, Pakistan, a dream was born. Mian Muhammad Sharif laid the first stone of a journey that would span generations.

What began with a few tools and endless determination evolved, through grit and relentless hard work, into Ittefaq Foundries Ltd. By 1971, Ittefaq Foundries had grown into Pakistan’s largest steel and heavy engineering enterprise, the crown jewel of the Ittefaq Group and a symbol of national industrial pride.

Yet, history often tests the greatest of legacies.

December 1971 brought the fall of Dhaka, severing their operations in East Pakistan.

Two weeks later, in Lahore, Ittefaq Foundries was nationalized without compensation, years of blood, sweat, and ambition wiped out overnight.

Yet even stripped of their assets, the spirit of resilience, deeply embedded by Mian Muhammad Sharif, could not be broken.

Rekindling the Legacy

The family did not mourn, ٱلْحَمْدُ لِلَّٰهِ they rebuilt

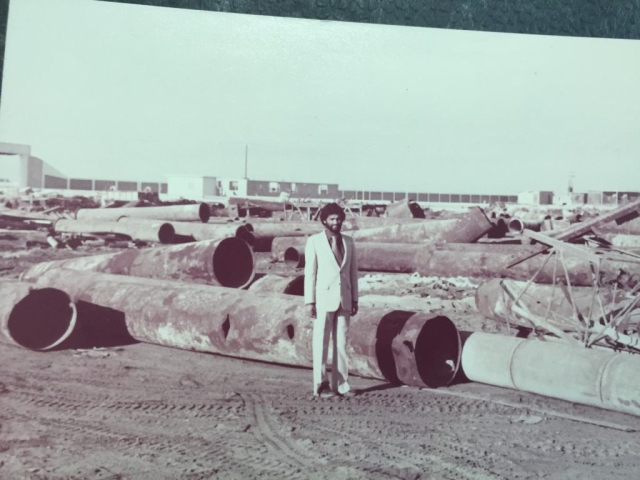

In 1972, they ventured beyond borders, with the establishment of the GCC’s first steel manufacturing plant in the UAE, a symbol that their spirit knew no boundaries. The mill was subsequently sold.

Undeterred by the era’s nationalization drive, between 1972 and 1977 they established five new industrial enterprises within just 18 months:

- Ittefaq Brothers

- Ilyas Enterprises

- Nawaz Shahbaz Enterprises

- Javed Parvez Enterprises

- Khalid Siraj Industries

In 1979, the devastated Ittefaq Foundries were returned to the family. And true to their nature, they invested millions to resurrect it from ruins.

The 1980s became a golden era:

- Ittefaq Textile Mills spun into life.

- Brothers Steel Mills expanded their steel empire.

- Ittefaq Sugar Mills began production, its machinery a testament to their in-house engineering excellence.

- Brothers Textile Mills, Khalid Siraj Textile Mills, Ramzan Buksh Textile Mills, and Brothers Sugar Mills soon followed.

Despite political hurdles and financial embargoes, the Ittefaq Group thrived, becoming Pakistan’s largest industrial group by the late ’80s, employing thousands and fuelling national growth.

Trials, Sacrifice, and New Beginnings

As the third generation matured, 1990 brought a voluntary division of the Group among the seven families.

Steel businesses remained collectively owned, while other assets were distributed individually.

Mian Muhammad Sharif retained only Ramzan Sugar Mills and a modest textile unit, Khalid Siraj Industries, a humble share for a man of his stature.

Between 1990 and 1998, the family forged ahead with new ventures:

- Hudabiya Paper Mills

- Hamza Board Mills

- Chaudhry Sugar Mills

- Hudabiya Engineering

Passing the Torch: From Mian Muhammad Sharif to Hussain Muhammad Nawaz Sharif

Inspired by the core values of Mian Muhammad Sharif — integrity, hard work, resilience, and excellence, Hussain Nawaz, equipped with a law degree from the London School of Economics and the entrepreneurial spirit of his forefathers, embarked on rebuilding from the ground up.

In 2001, amidst the unforgiving desert landscape near Makkah, a nascent rebar manufacturing unit was established and meticulously cultivated into a fully integrated industrial facility, a distinguished embodiment of foresight, determination, and ambition. By 2006, the enterprise underwent a seamless transition through a family settlement, heralding the dawn of a new chapter in industrial excellence.

The Birth of Al Tilal Steel (2005 – 2025 and Beyond)

Al Tilal Steel Company Limited was founded in 2005 in Jeddah, Saudi Arabia.

From day one, Al Tilal carried the torch of its heritage forward.

2008

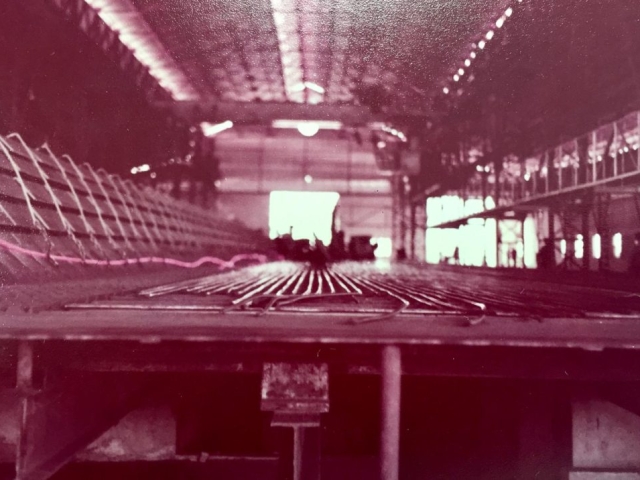

Melt Shop

induction furnaces

F.E.S

To keep the environment Clean

Building the Foundations

- The Melt Shop began operations, commissioning modern induction furnaces.

- A Fume Extraction System was installed, early proof of Al Tilal’s commitment to environmental leadership.

Strengthening the Core

- Al Tilal expanded into rebar production, launching a cutting-edge rolling mill.

- The company became a key player in Saudi Arabia’s booming construction sector.

2010

Rebar Production

Rebar Production started in 2010

2015

FES Upgrade

In 2015 a major upgrade in FES

Driving Innovation

- A major upgrade to the Fume Extraction System.

- Tens of millions invested in environmental technologies.

Gaining Global Recognition

- Certified ISO 9001:2015 for Quality and ISO 14001:2015 for Environmental Management.

- Achieved CARES certifications (BS4449 and ASTM A615/A615M).

- Became an approved vendor for Saudi Aramco — a mark of unmatched industrial credibility.

2018

2020

Sustainability

Embracing Vision 2030

- Launched major sustainability and efficiency initiatives.

- Secured SASO certifications for ASTM A615M:2021 and ASTM A706M:2018 standards.

Leading Environmental Stewardship

- Partnered with Nikko Ind. Ltd. (Japan) to upgrade fume systems.

- Commissioned a Radiation Monitoring System at the plant gate for enhanced safety.

2021

FES Upgrade

Major Fume Extraction System Upgrade

Radiation Monitoring

Radiation Monitoring System for Enhanced Safety

2023

Increased FES Capacity

Raising the Bar for Sustainability

- Increased fume extraction capacity to 900,000 m³/hour.

- Launched a roadmap targeting carbon neutrality by 2035.

Innovation and Diversification

- In December 2024 by successfully commissioned an independent Primary FES with a capacity of 240,000m3/hr installed for our 3rd furnace.

2024

New Primary FES

New Commissioned FES with a capacity of 240,000m3/hr installed for our 3rd furnace.Description

2025

AOD

Wet Scrubber

Innovation and Diversification

- Initiated expansion into engineering steels and specialized products.

- Integrated smart environmental technologies across operations.

- Set ambitious new targets for green transformation and circular economy practices.

The Birth of Al Tilal Steel (2005 – 2025 and Beyond)

Al Tilal Steel Company Limited was founded in 2005 in Jeddah, Saudi Arabia.

From day one, Al Tilal carried the torch of its heritage forward.